Forge & Foundry Grinding

The requirement for significant physical operator input on most swing frame grinder systems has a hugely negative impact on grinder safety and efficiency.

At Clansman, our approach is different. Clansman grinders are controlled entirely from the safety of a cabin, using our intuitive and precise control system. That means no more operator fatigue, improved safety and better efficiency.

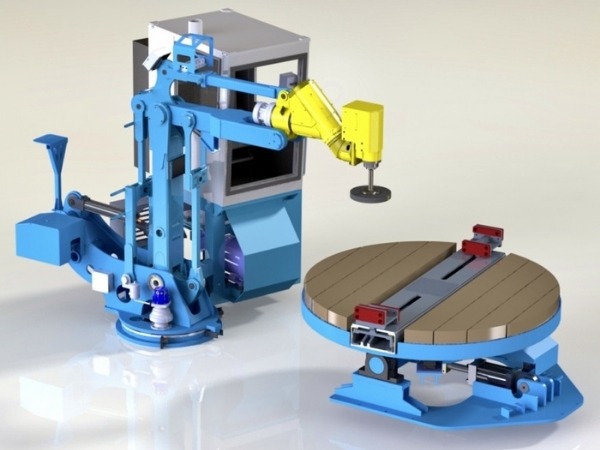

G45 Grinder

Our G45 grinder is a vastly improved upgrade to any traditional swing frame grinder. We estimate the G45 can complete the work of approximately 8 conventional machines with superior precision and safety. When coupled with a Clansman turntable, the G45 offers additional flexibility, allowing castings to be ground on all surfaces.

Highlighted Features

- 45Kw electric motor driving a grinding spindle through a multiple “V” belt drive.

- 4 axes of moment – vertical, horizontal, slew and roll.

- The grinding head can tilt ±20°

- 500mm diameter grinding wheel

- Suited for heavy-duty grinding on flat surfaces

Contact

a.smith@clansman Tel: 00123694616

G30P Grinder

The G30P Grinder offers even more versatility than the G45 machine. Featuring an enhanced control system, the G30P delivers excellent precision and accuracy when grinding. This machine uses a smaller, more flexible grinding head that allows the G30P to reach more challenging casting areas.

You can also fit a Delta Motion Controller offering additional pressure and position controls. This allows operators to follow a surface and achieve consistent material removal over a selected area.

Highlighted Features

- 30kW hydraulic motor driving a grinding spindle through an individual power unit

- 5 axes of movement – vertical, horizontal, slew and 2 axes of roll

- Grinding head utilizes 360° movement

- Wide range of different grinding stones and cutting disk options.

- 500mm diameter grinding wheel

- The delta controller has a “teach and learn” facility for semi-automatic grinding

Contact

a.smith@clansman Tel: 00123694616

C620G Grinder

The C620G is the largest grinder in our range. The machine excels with much larger castings and heavy grinding. The grinding head on these machines is large to allow it to transmit its full power potential efficiently.

This style of grinder is regularly used at windmill casting manufacturers.

Highlighted Features

- Designed for powers from 55Kw to 110Kw

- Option for a wider variety of tools such as 815mm cutting disk

- Axes of movement – vertical, horizontal, slew, yaw, pitch and roll.

Contact

a.smith@clansman Tel: 00123694616

Our grinders are powerful, productive, precise and safe

One of our team would be happy to talk to you about your project to see if Clansman Dynamics could be the right solution for your business.